Contact VariaLift Airships on 07753 420565

Navigation

Patents

Protected by:

European Patent No.

» 1591356

USA Patent No.

» 7568656

Hong Kong Patent No.

» HK 1083614

I.P. Patent Pending

Register Your

Interest

For updates on the concept development of this unique concept, please send us your details and we will keep you in the loop.

News & Events

Manufacturing site progress report, January/June 2019

Assembly towers made of containers have been customized and prepared for the assembly of the module canopies and helium tanks. The overhead of height 30 meters and span 27 meters crane was tested, assembled and placed on its rails. The assembly of the cargo bays has begun.

Manufacturing site progress report, July/December 2018

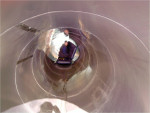

The Plate material finally arrived and the first jigs for helium tanks were set up. Sections of tanks have since been produced in number. These 1250mm sections will eventually be welded together to form 2500mm sections.

The construction of the 30 m high, 27 m span overhead crane that will be used to assemble the modules of the airship started. The railway tracks were set up and a cement bridge constructed to allow 200m roll of the crane.

The helium bag manufacturing hanger was prepared including a suspended ceiling, special tables were made and an airtight dust-free filtered space created. The first bags made and tested sucessfully.

The jigs for making the helium containing cylinder ends were made and production of first domes began. Additional cylinder assembly began.

Manufacturing site progress report, January/June 2018

More cementing continued as the bases for the two assembly carrousels were cast. These carroussels will serve to pivot the tanks as well as the semicircular frames so that welding and consolidating can be done without the welder/rivetter needing to move from his sheltered position in the Container tower that is to be built at a later stage.

The first jigs and fixes for the base structures and cargo hold were set in place with milimetric precision. Various additional deliveries of aluminium and production began.

Manufacturing site progress report, July/December 2017

The jigs for the helium tank were made and production initiated. 128 cement cubes were cast to finalize the foundations on which the structure is to be assembled. Work advanced on more complex semicircular frames

Manufacturing site progress report, May/June 2017

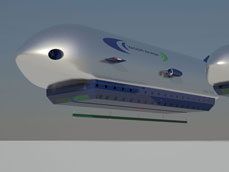

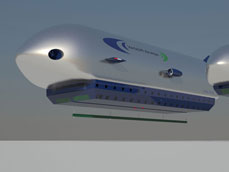

Good progress has been made with the welding of the cargo bay and work has started on the semicircular frames which will form the top of the prototype airship (ARH-PT). The attached photos show parts of the cargo bay structure of the first module which have been moved out of the welding bays onto the outdoors assembly site. The parts will shortly be welded together.

The other photos show CEO Alan Handley levelling the wooden "jig" on which we are building the semicircular frames. The frames will be around 40 metres along the curve, 25 metres in diameter.

Agreement has also been reached with a Canadian partner on the manufacture of the helium bags for the prototype. Fabrication of a sample bag is under way, which we will test for helium tightness.

We are now awaiting delivery of the metal which will form the cylindrical pressure tanks. These will be shaped and sealed with helium tight welds.

Older reports

Manufacturing site progress report, March/April 2017

After some delays due to supplier difficulties, metal for building the pilot trainer/prototype (ARH-PT) finally arrived at the site in the middle of March and welding of the cargo bay began immediately (see pictures below). In the mean time staff have been busy improving site security and lighting, preparing buildings, clearing vegetation from the manufacturing site and installing new drainage. This work was led by a team from Stourbridge-based Twin Oaks Limited (twinoaksltd.co.uk), under the inspired leadership of Neil Hendrie.

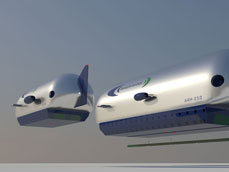

Welding of aluminium for the airship and steel for the manufacturing arch will be carried out in separate buildings to minimise contamination. The first of the four central modules of the ARH-PT should be completed and ready for testing in May. The remaining three modules (with nose and end cones) will follow and the completed airship should be ready for flight testing in late summer 2019.

Manufacturing site progress report, December 2016/January 2017

Interviews for the staff who will construct the ARH-PT took place on 29 and 30 November, and ten employees have been selected. Three employees started work in December. Construction, electrical and plumbing/drainage work continues at the site (see pictures below). Welding will start in January 2017. This [http://bit.ly/2gb7Qry] article in the Echo Republicain newspaper gives more detail in French. It has been a busy period with several visitors to the site including senior military officers, municipal and regional figures.

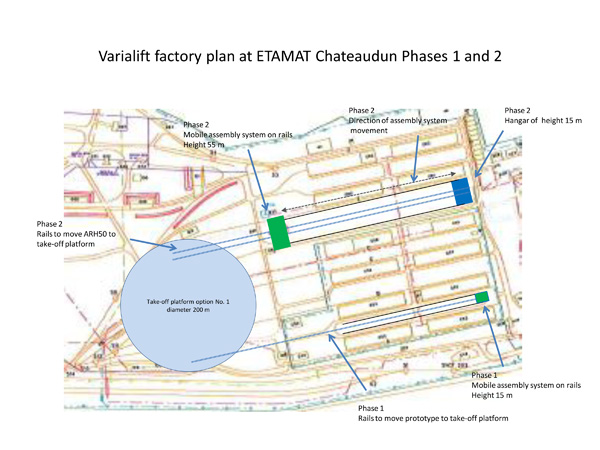

The sketches below show the location of the production lines and the proposed airship take off circles (Varialift airships take off vertically and do not need runways, but will need to rotate so that they are facing the wind.)

Varialift Business Development Director Ernesto Soria has been appointed as Operations Supervisor at the Chateaudun site. He gave an interview to France 3 television coinciding with the signature of the first Varialift France employment contract which aired on 1 January 2017.

Manufacturing site progress report, 4 November 2016

The ARH-PT production line will be set up in the north-east corner of the 40 hectare site to the south of Chateaudun. Work to clear overgrown areas was completed in September 2016. Electricity and water supplies were connected at the end of October. Work to secure the site and key buildings will take place throughout November and December prior to the construction of the aluminium base above which structural welding is to take place, starting in the new year. Completion of the first ARH-PT is expected in summer 2019, when flight testing will commence.